Catalytic Converter eCommerce Packaging

Team Members:

- Meredith Brooks

- Jordan Evans

- Ben McMurray

- Jack Thompson

- Shane Yuhasse

Objective:

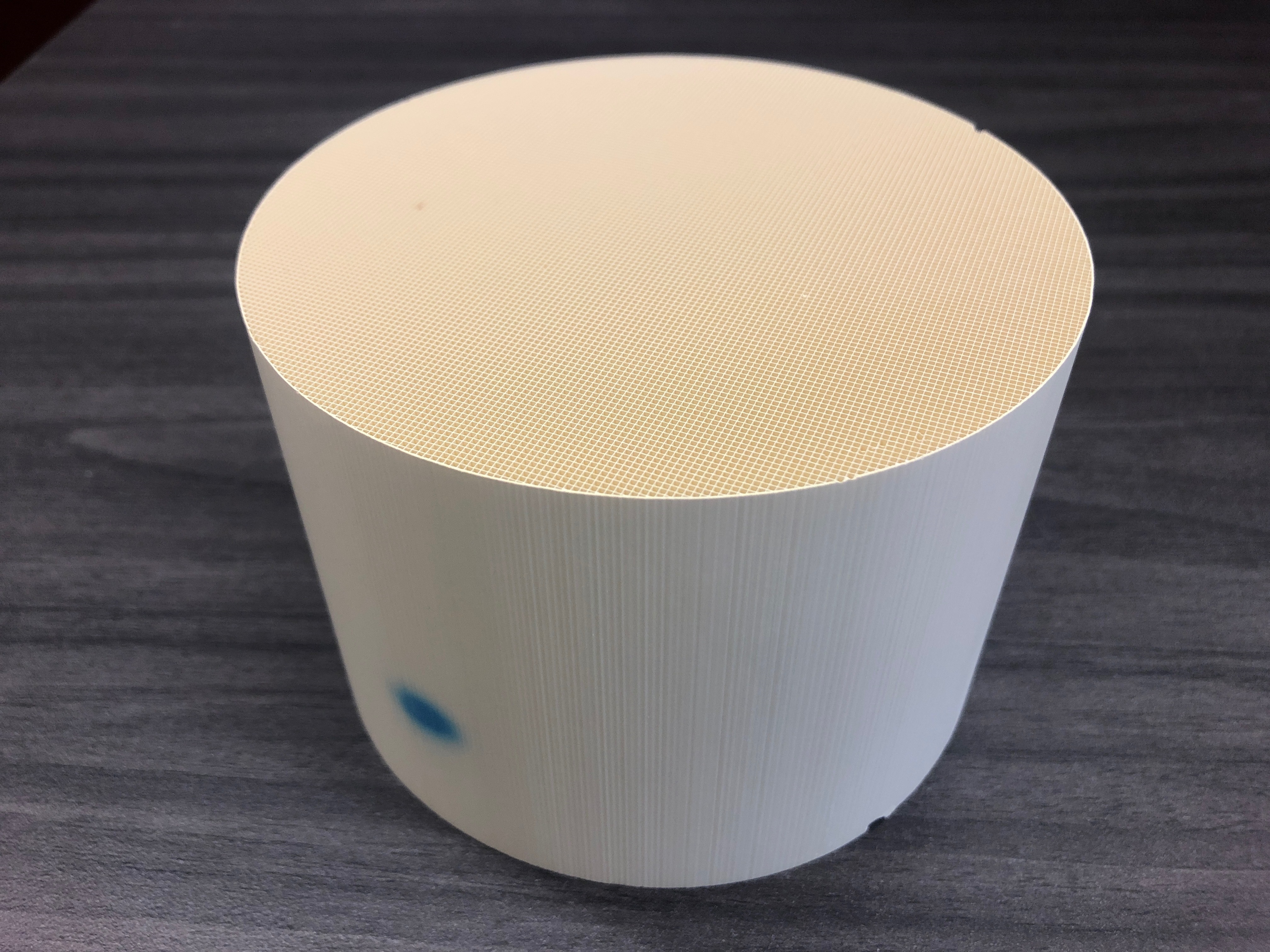

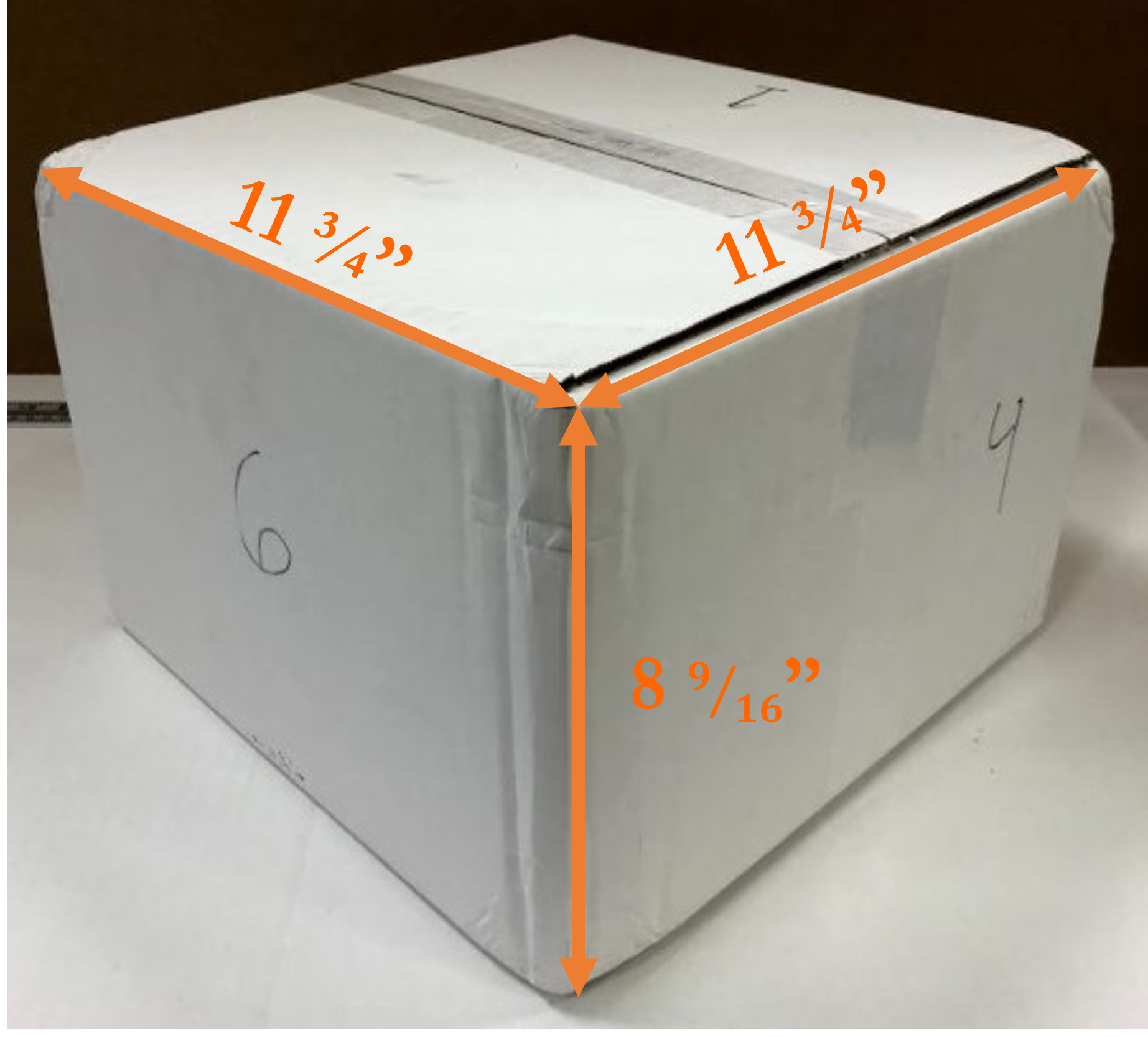

- To package eight ceramic catalytic converters for eCommerce according to ISTA 6A standards.

Solution:

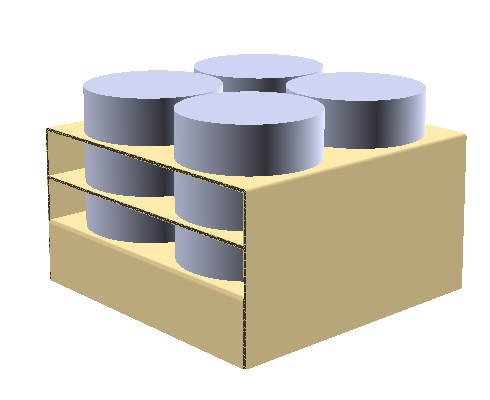

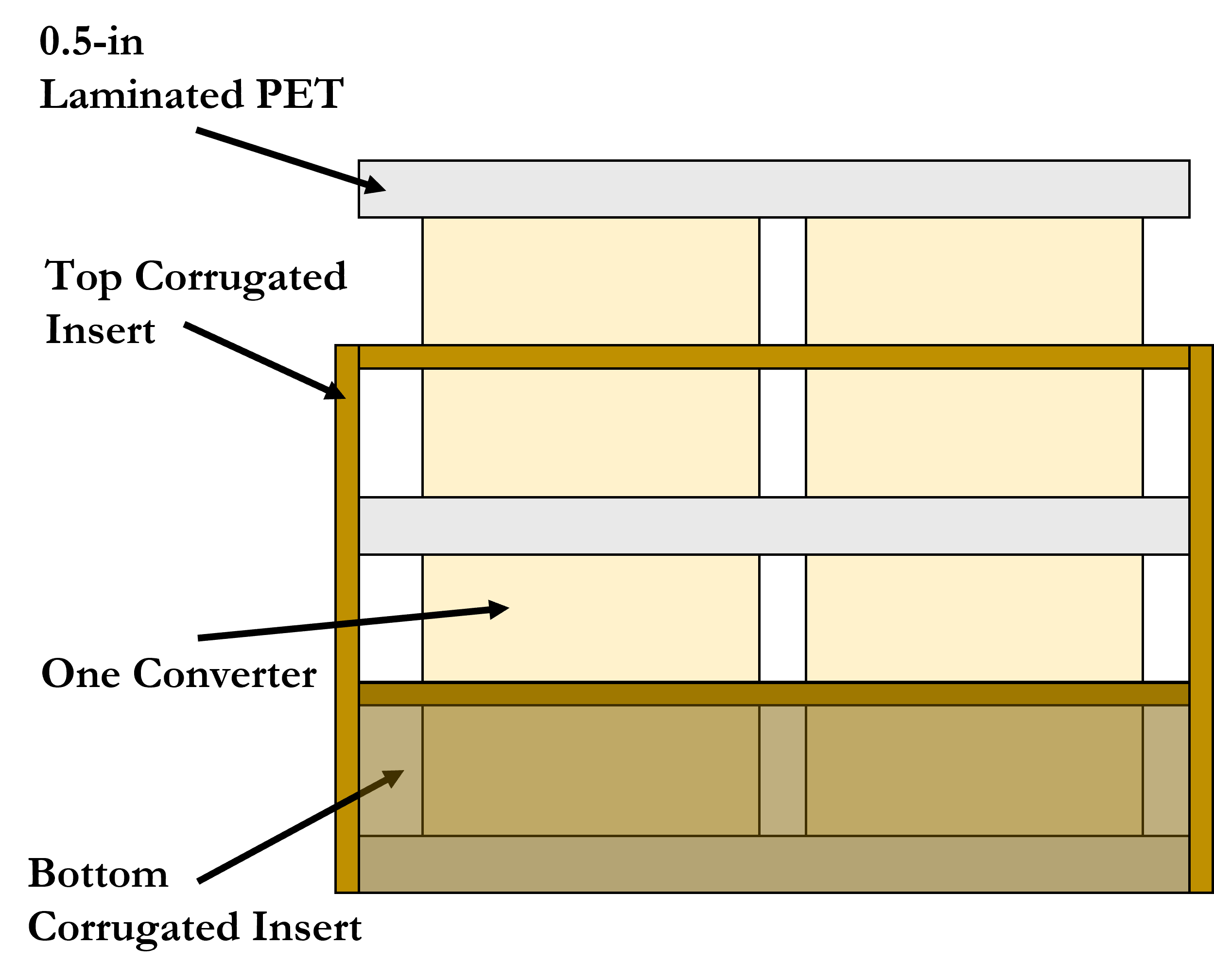

- A C-flute Center Special Slotted container with three foam cushions to protect the converters from shocks.

- Two C-flute inserts and Ranpak Geami paper hold the converters in place.

Challenges:

- Adequately protecting the ceramic cylinders while minimizing material use.

- Finding a recyclable alternative to conventional foam cushions.

- Navigating in-person lab restrictions due to COVID.

Successes:

- Minimized shipper size by stacking the converters in two layers of four.

- Absorbed the shock from drops with the combination of corrugated inserts and foam cushions.

- Reduced physical waste by 41% in comparison to conventional packaging solutions.

Potential Improvements:

- Use an RSC instead of a Center Special Slotted container to further reduce material use.

- Eliminate the use of Ranpak Geami paper.

- Use thicker cushions with circular cutouts to eliminate the use of corrugated inserts.